WELDER QUALIFICATION TEST

In the context of welding, WQT stands for "Welding Procedure Qualification Testing," which is a series of tests performed to qualify a welding procedure for a particular application. Fillet welds and butt welds are two common types of welds that can be subjected to different WQT testing procedures.

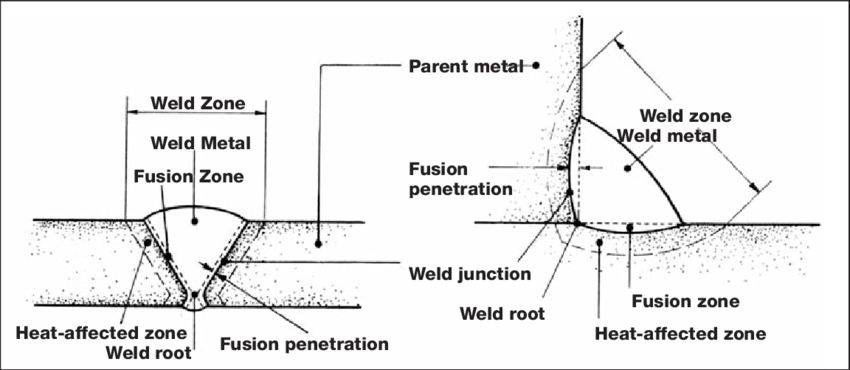

Visual Inspection

The appearance and quality of the weld are visually inspected to ensure it meets the specified requirements.

The WQT test for fillet and butt welds usually includes the following steps:

Tensile Test

Tensile testing is performed to evaluate the strength of the weld and its ability to withstand pulling forces.

It's important to note that specific WQT testing requirements may vary depending on the applicable welding standard, material, thickness, and intended application. Qualified welding procedures ensure that welded components meet the required strength, quality and safety standards for the intended application. The inspection process helps ensure that welding procedures are performed correctly and that reliable and durable welded joints are produced.

Standards we tested to

| Sr. No. | Discipline: Welder Qualification Test | Test Methods |

| 1 | Fillet Weld &Butt Weld | BS EN ISO 15614-1:2017, ASME SECTION IX:2021, BS EN ISO 4136:2022, AWS D1.1/1.2A:2020, ISO 9017:2017, ASME SEC IX:2021, IS 3600-9:2022, ISO 17639:2022, IS 2825:2022, IS 3600-8:2019 |