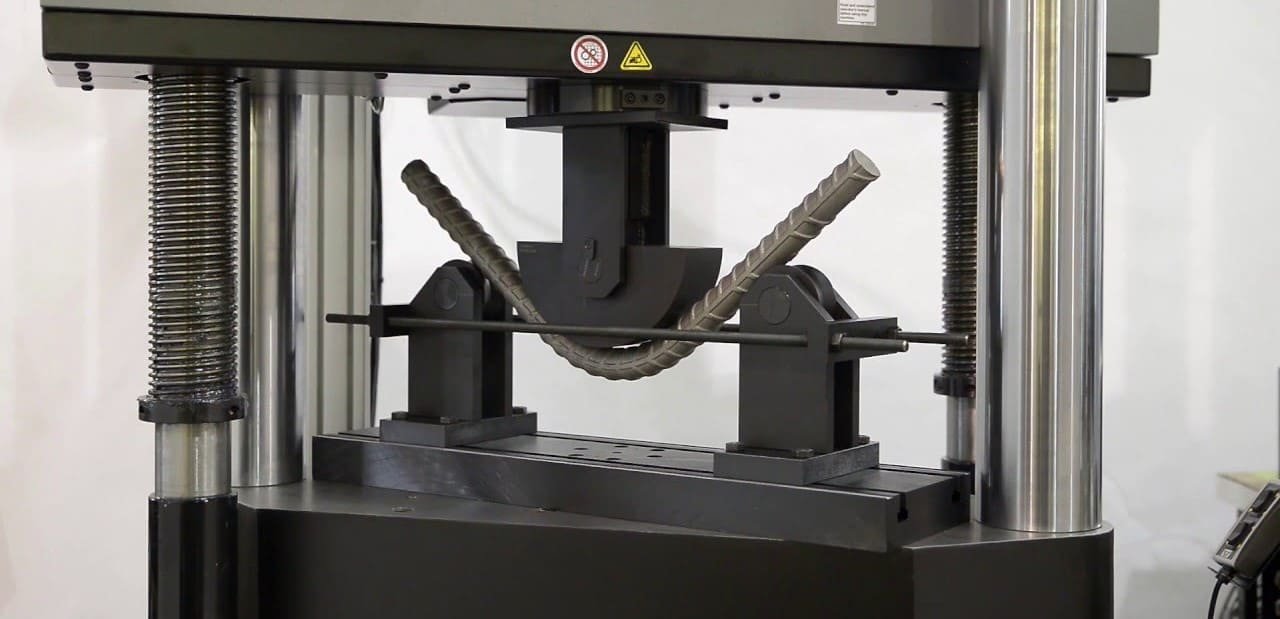

Bend/Rebend Test

The level of rigidity of the metal to be made (often sheet, strip, plate, bar, and wire) is measured throughout this process. In addition, it is used to evaluate the strength and hardness of metal (after welding, etc.). The sample is typically bent over a tool with a fixed diameter. Free, guided, semi-guided, and wrap-around bend are the four common types of bends, according to ASTM E290, E190, A370, and various IS, BS, and ISO standards.

Purpose

The bend test is used to determine the material’s ductility and flexibility. It serves in figuring out the material bending capacity without breakage or failure.

Bending Techniques

Depending on the material and the test requirements, different bending procedures are used. Three-point bending, four-point bending, and mandrel bending are popular procedures.

Evaluation Criteria

Doing bend test of a material, a number of factors are evaluated, including the angle of deflection, the existence of cracks or fractures, and the material’s capacity to recover its former shape.

Standard we tested to

| Sr. No. | Discipline: Bend Test | Test Methods |

| 1 | Reverse Bend Test | ASTM A249: 2018, IS 1786: 2018 |

| 2 | Bend Test | ASTM A370: 2022, IS 1599: 2019, ASTM E290: 2022, BS EN ISO 7438: 2020, AWS D1.1/1.1M: 2020, ASTM E190: 2021, ASME SEC IX: 2021, BS EN ISO 5173: 2009, AWS D1.6/D1.6M: 2017, IS 3600-7: 1985, IS 3600-5: 2018 |