Magnetic particle inspection

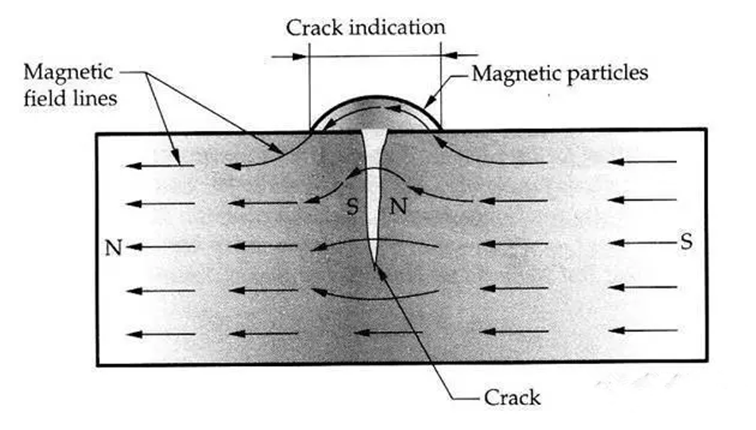

As a recognised non-destructive testing technique, magnetic particle inspection (MPI), often referred to as magnetic particle testing (MT), is used to find cracks and other problems on the surface and near-surface of ferromagnetic materials. OMSPL Lab, an accredited third-party testing organisation, can offer magnetic particle inspection (MPI) services in accordance with ISO, ASTM, and industry standards.

Magnetic particle testing methods

- Wet method

The wet method is the use of magnetic powder suspended in oil, water, or another liquid medium for the detection process. This method shows the shape and size of the defect by utilising the flow of the carrier liquid and the attraction of the magnetic powder by a leakage magnetic field. Due to the magnetic suspension’s performance in terms of dispersion and suspension, the size of the magnetic powder particles that can be used in wet detection is smaller. It has a high detection sensitivity as a result.

- Dry method

Dry technique is also known as the dry powder technique. When the wet approach cannot be used for testing, a particular dry magnetic powder is applied directly to the magnetised workpiece in accordance with the protocol, and the workpiece’s flaws leave magnetic traces. Dry inspection is typically utilised in conjunction with portable equipment for local area examination of big castings, forgings, structures, and weldments.

Magnetic particle inspection process

The magnetic particle testing methods utilised vary depending on the material, shape, and size of the examined parts as well as the type, location, direction, and shape of the flaws to be checked, but the overall testing procedure is generally as follows:

- Preparation before testing: Examine the sensitivity of the testing equipment and clean the examined parts’ surfaces of oil and rust.

- Magnetization.

- Spray magnetic suspension or powder.

- Analysis and observation of magnetic markings.

- Demagnetization.

- Cleaning, drying, anti-rust.

- Record the results: Keep track of the magnetic procedure, specimen condition, magnetic current, mode, interpretation and evaluation of magnetic markings, test date, operator and assessor, and final test results.

Industries of magnetic particle inspection (MPI)

- Aerospace

- Automotive

- Petrochemical

- Structural steel

- Power generation

- Pipelines

Standards we test:-

- ASTM E709-15, ASTM E1444, ASTM A275, ASTM E3024, ASTM A966, ASTM E3022-18, ASTM A986

- ISO 4986, ISO 13665, ISO 13664, ISO 10893, ISO 23278