Dye penetrant Test

Dye Penetration Test

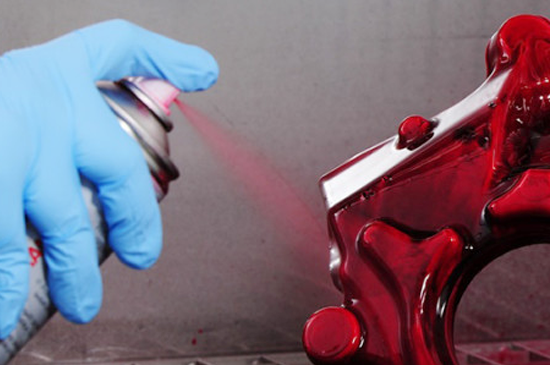

At Om Metalab Services Pvt. Ltd. the dye penetration technique, a penetrating liquid is applied to the component's surface in order to penetrate the crack or discontinuity. The penetrant that flows from or is sucked back out of the crack is then seen after the excess penetrant has been removed from the surface.

Testing with liquid penetrants can be done on any non-porous, clean material, whether it be metallic or not, however it is not recommended for surfaces that are extremely rough or unclean. A dye may be present in penetrants to make the indication visible under white light, or a fluorescent substance may be present that fluoresces when exposed to the proper ultraviolet light. When maximum fault sensitivity is desired, fluorescent penetrants are typically used.

- Dye penetration inspection is used extensively for the testing of wrought and cast products of ferrous and non-ferrous metals, powder metallurgy parts, and ceramics and glass objects. Advantage of PT are that it can be check all type and shapes,

- It is very simple method to test and train to people, Very low cost, it can be use on field and also for mass production. In PT we have all type of set up for Visible or fluorescent testing water washable, post-emulsifying and solvent technique. We are provide this services on filed also. We have qualified and experience staff for all type of testing and material